The cooling energy consumption in data centers can account for about one-third of the total energy usage. It is evident that a reasonable cooling strategy is crucial for the economic and social benefits of data center operations. Once a data center is constructed, the climatic conditions of its location are fixed. After the layout of the data center and the cooling equipment are determined, the organization of airflow within the data center becomes a key and challenging aspect to ensure reliable operation while reducing energy consumption.

Principles of Optimizing Airflow & Cooling in Data Center

Cold Airflow: Avoid waste; aim for directed supply and targeted cooling.

Hot Airflow: After exiting from the equipment cabinets, try to prevent mixing with the cold airflow in the room; this will increase the return air temperature for the air conditioners, enhancing the heat exchange efficiency of the evaporators.

Air Supply: Maintain clear air paths; unless necessary, minimize the load on fans.

There are many existing methods of airflow organization that can broadly be divided into two categories: top-supply and bottom-supply. Each category includes four typical methods of airflow organization, making a total of eight airflow techniques.

4 Typical Underfloor Cooling Supply Methods

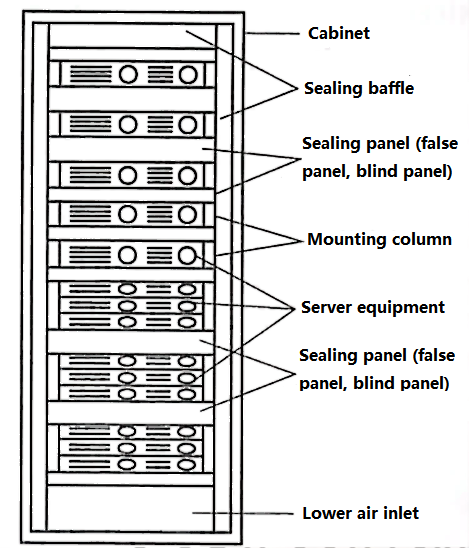

1. UnderfloorAirflow (Raised Floor) + Sealed Cabinet Airflow

Cold air is supplied under the raised floor (similar to a plenum) into the IT cabinets, absorbing heat from the IT equipment, and then the hot airflow exits from the rear or top of the cabinet back to the air conditioner.

Features: Standard cabinets at the front have sealed air cabinets; the layout of cabinets is flexible, can be back-to-back or in the same direction; low investment and standardized construction are very convenient.

Suitable for: New projects only; however, the size of the air cabinets limits the airflow of the cabinet, typically suited for individual power densities below 3kW.

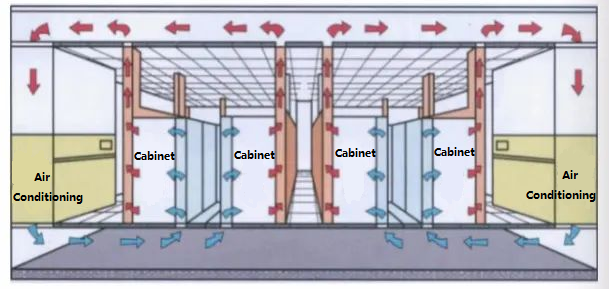

2. UnderfloorAirflow (Raised Floor) + Cold Aisle

Cabinets are arranged face-to-face in rows and achieve a closed cold aisle, forming a “cold pool.” Air conditioners supply cold air through the plenum under the raised floor into this cold pool, where it undergoes a secondary pressure equalization before cooling the IT equipment. Hot airflow exits from the rear or top of the cabinet back to the air conditioner.

Features: The closed cold aisle helps in secondary balancing of airflow, making the air intake more consistent across cabinets at various distances from the air conditioner, and keeping the temperature difference at different heights within the same cabinet below 2°C, effectively avoiding uneven hot and cold spots.

Suitable for: Cabinets with a power density of 4-8kW; for cooling higher density servers, increasing the area of the cold pool or installing an active floor for additional cooling might be necessary.

3. UnderfloorAirflow (Raised Floor) + Hot Aisle

Cold air is supplied under the floor near the cabinets, and the hot aisle is enclosed; hot air is ducted into the ceiling back to the air conditioner.

Features: Energy-efficient but requires high investment, not easy to construct, and not suitable for evaporative air conditioning in data centers. Hot air needs to be forcibly extracted back to the air conditioner; this method is rarely used in practice.

Suitable for: New projects using water-cooled air conditioning, with individual power densities of 5-8kW.

4. UnderfloorAirflow (Raised Floor) + Active Floor + Cold/Hot Aisles

Cold and hot aisles are enclosed in the data center. Cold air is supplied under the floor, partly using an active floor, and after secondary pressure equalization in the cold pool, it enters the equipment cabinets. Hot air is ducted into the ceiling back to the air conditioner.

Features: This is a combination of methods 2 and 3, suitable for ultra-high heat solutions, but the investment is very high.

Suitable for: New data centers, with cabinet power densities reaching 12-20kW.

4 Typical Overhead CoolingSupply Methods

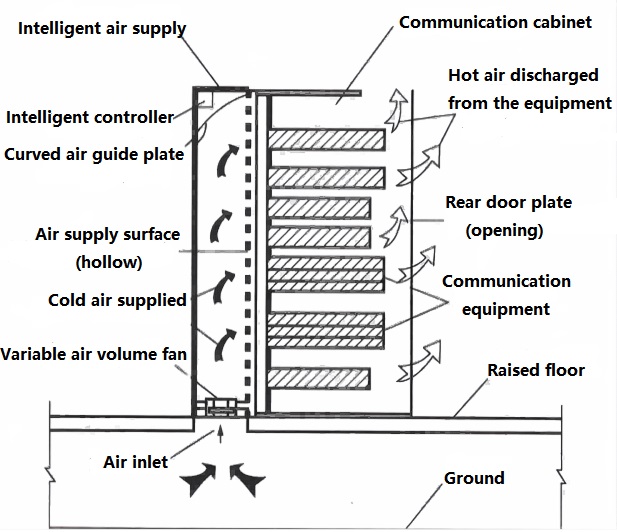

1. Overhead Airflow + Ductwork + Bottom or Directed Air Supply

Cold air is transported to the vicinity of the cabinets via ductwork, volume control dampers, and air outlets. Depending on the position of the ductwork and cabinets, bottom or directed air supply is used, but the cold airflow cannot avoid mixing with the hot airflow before entering the servers.

Features: Adjustable air volume and direction, low investment, and eliminates the need for a raised floor.

Suitable for: Renovation or new projects, with data center power densities not too high, suitable for individual cabinet densities of 1-2.5kW.

2. Overhead Airflow+ Ductwork + Direct Cold Air to Cabinet

Cold air is directly supplied to the equipment cabinets via ductwork, volume control dampers, and door panel type air handlers. This method involves a more complete enclosure of the cold aisle, representing a precise air supply in the strict sense. This form of air supply must consider redundancy and backup of adjacent air conditioning units; if one fails, the neighboring units should provide emergency cold airflow through the connected plenum.

Features: Adjustable airflow for each cabinet, but the ductwork production costs are high, and the investment is significant.

Suitable for: Suitable for some old data centers being renovated, applicable to individual cabinet densities of 2-3kW.

3. Overhead Airflow+ Ductwork + Cold Pool

Cabinets are arranged face-to-face, with a closed cold aisle, and air is supplied to the equipment cabinets via ductwork, guide cabinets, and a sealed cold aisle for secondary pressure equalization.

Features: A high-heat data center solution, with reasonable airflow organization and significant investment.

Suitable for: Suitable for new projects based on some old data centers, applicable to individual cabinet densities of about 5kW.

4. Overhead Airflow + Ductwork + Direct or Directed Air Supply or Bottom Air Supply

This is a hybrid method, suitable for data centers where the power consumption of cabinets varies significantly. Cabinets that can be enclosed use a closed cold aisle, and those that cannot be enclosed use an open approach. However, the outlet airflow from the ductwork is adjustable and is positioned as close as possible to the equipment’s air intake, achieving partial area precision air supply and differentiated cooling solutions for cabinet cooling demands.

Features: A comprehensive application of the earlier methods.

Suitable for: Renovation projects, especially complex, non-standard sites, based on the main equipment requirements. Since it involves top-supplied air through ductwork, the individual cabinet power should not exceed 2.5kW; otherwise, additional airflow and cooling should be provided.

In practice, most data centers use top-supply or bottom-supply methods for cooling. From practical results, because the heated cold air naturally rises, the effectiveness of bottom-supply airflow is superior to that of top-supply, benefiting equipment cooling and reducing fan power consumption. If the conditions of the data center allow, it is advisable to use bottom-supply air methods as much as possible, considering different cabinet power density requirements, and deciding whether to establish cold or hot aisles, with cold aisles generally performing better than hot aisles.

Huiya Real-Time News

Huiya Real-Time News is dedicated to providing you with the latest and most authoritative information on the raised flooring industry.

We provide 24/7 updates on industry policy interpretations, market trend analysis, company news.

匯亜、新たに塩霧試験装置を導入 OAフロアの品質防線を強化

회아, 새 염무시험장비 도입해 이중바닥재 품질 방호선 단단히 만듦

창주 회아 이중바닥재 회사, 한국 KSA 인증 획득하며 이중바닥재 공식 한국 수출 시작

MORE DOWNLOADS

GENERAL CATALOGUE

HUIYA INTRODUCTION

HUIYA GREEN LABEL

CAD/BIM FULL STEEL

APPLICATION SCENARIOS