In the world of modern architecture and design, the concept of a raised floor has revolutionized the way we think about space utilization. Whether it’s in commercial buildings, data centers, or even residential spaces, raised floors offer a versatile solution that blends functionality with aesthetics. But have you ever wondered just how much weight these elevated platforms can bear? Prepare to delve into a captivating exploration as we unveil the remarkable weight-bearing capabilities hidden beneath these seemingly ordinary surfaces. From heavy machinery to bustling foot traffic, join us as we unravel the secrets behind the extraordinary strength of raised floors and discover the boundless possibilities they hold. Get ready to redefine your understanding of structural prowess and embrace the true potential of raised floors like never before.

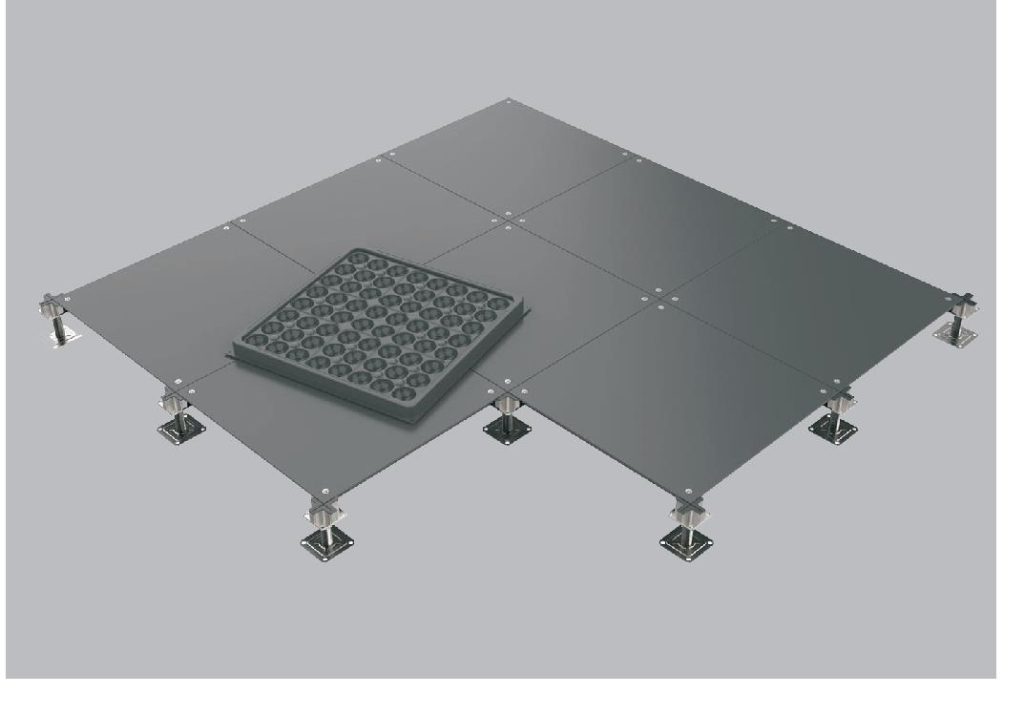

Raised floors, also known as access floors or raised access floors, have become an integral part of modern buildings, particularly in the realm of commercial and data center environments. These versatile systems provide a concealed space beneath the floor surface, allowing for the efficient management of various utilities, including electrical, data, and HVAC (heating, ventilation, and air conditioning) systems. One crucial consideration when designing and utilizing raised floors is their weight-bearing capacity. In this article, we delve into the factors that determine the weight capacity of raised floors and explore the range of loads they can safely support.

1. What is the Load Capacity of Raised Floors?

The load capacity of a raised floor refers to the maximum weight or load that the floor system can safely support without experiencing structural failure or damage. It is an important consideration when designing and installing a raised floor, particularly in environments where heavy equipment or machinery will be placed on the floor.

The load capacity of a raised floor is typically measured in pounds per square foot (psf) or kilograms per square meter (kg/m²). The actual load capacity can vary depending on the type of raised floor system and its design specifications.

Standard raised floor systems commonly have load capacities ranging from 1,000 to 2,500 psf (4,882 to 12,207 kg/m²). This capacity is usually sufficient to support the weight of office furniture, computer equipment, and foot traffic. However, it’s important to note that specialized heavy-duty raised floor systems can be designed to accommodate higher load capacities as needed for specific applications.

In environments that require higher load capacities, such as data centers or server rooms with heavy equipment, the load capacity can exceed the standard range. In such cases, the load capacity is often determined through structural analysis and engineering calculations, considering factors such as the type and weight of the equipment, distribution of loads, and the overall design of the raised floor system.

To ensure the safety and proper functioning of a raised floor system, it is crucial to consult with a structural engineer or the manufacturer of the raised floor system to determine the appropriate load capacity based on the specific requirements of your project.

2. Factors Influencing Weight Capacity

Several factors influence the weight capacity of raised floors. Understanding these factors is crucial for determining the safe load limits and ensuring the longevity and functionality of the raised floor system. Here are the key elements to consider:

Pedestal Strength and Spacing

The pedestals serve as the primary support structure for raised floors. They are usually made of steel or other robust materials, designed to withstand substantial loads. The strength and spacing of the pedestals directly impact the overall weight capacity of the raised floor system. Manufacturers provide load tables and specifications that outline the maximum weight a floor can bear based on pedestal spacing and type.

Panel Construction and Materials

The construction and materials of the raised floor panels significantly affect their load-bearing capacity. Steel panels are generally the strongest and can support heavy loads. Aluminum panels are lighter but still offer substantial weight capacity. Wood panels are more suitable for light to medium loads. Manufacturers typically provide load ratings for their panels to guide the design and installation process.

Panel Size and Layout

The size and layout of the raised floor panels play a crucial role in determining the weight capacity. Larger panels generally distribute loads more efficiently, reducing stress concentrations. Additionally, the panel layout, including the arrangement of pedestals, needs to be carefully considered to ensure uniform weight distribution.

Underfloor Obstacles and Cutouts

The presence of obstacles, such as columns or equipment, and the extent of cutouts in the raised floor system can affect its load-bearing capacity. These factors may compromise the structural integrity of the panels or restrict the even distribution of weight. Designers should account for these obstacles during the planning stage to maintain the integrity of the raised floor system.

3. Weight Capacity for Different Duty

Raised floors are classified into weight categories based on their load-bearing capacity. These categories help designers select the appropriate floor system for specific applications. Common weight categories include:

Light Duty

Light-duty raised floors are designed for office environments and areas with minimal foot traffic. They can support loads ranging from 250 to 500 pounds per square foot (psf). These floors are typically constructed with wood or aluminum panels and have narrower pedestal spacing.

Medium Duty

Medium-duty raised floors are suitable for areas with moderate foot traffic and light equipment loads. They can support loads ranging from 500 to 1,000 psf. Steel or aluminum panels are commonly used in medium-duty floors, with slightly wider pedestal spacing compared to light-duty systems.

Heavy Duty

Heavy-duty raised floors are engineered for areas with heavy equipment and high foot traffic. They have a load capacity ranging from 1,000 to 2,500 psf. Steel panels and robust pedestals with wider spacing are employed to handle these demanding loads.

Extra Heavy Duty

Extra heavy-duty raised floors are designed for specialized environments such as data centers, server rooms, and industrial facilities. These floors can support loads exceeding 2,500 psf. They utilize reinforced steel panels and sturdy pedestals with the widest spacing to accommodate extreme loads.

4. Load Distribution and Concentrated Loads

Proper load distribution is crucial to maintaining the structural integrity of raised floors. Concentrated loads, caused by heavy equipment or localized weight, can pose challenges to the system’s stability. To ensure the safe distribution of weight, designers employ various techniques, including the use of load spreaders or additional pedestals beneath concentrated loads.

5. Engaging Professionals and Compliance with Standards

When designing and implementing a raised floor system, it is essential to engage professionals with expertise in the field. Structural engineers, architects, and raised floor specialists can provide invaluable insights to ensure the system’s safety and efficiency. Compliance with relevant industry standards and building codes, such as those set forth by the Building Industry Consulting Service International (BICSI) or the International Electrotechnical Commission (IEC), is also essential.

The weight capacity of a raised floor system depends on various factors, including the strength and spacing of pedestals, the construction materials of the panels, the size and layout of the panels, and the presence of underfloor obstacles. Understanding these factors and adhering to weight categories enables designers to select the appropriate raised floor system for specific applications. By considering load distribution and engaging professionals in the design process, buildings can benefit from the functionality and versatility offered by raised floors while ensuring the system’s longevity and safety.

As technology advances and building requirements evolve, the demand for raised floors continues to grow. By staying informed about weight capacities and best practices, architects, engineers, and facility managers can make informed decisions and create optimized environments that meet the needs of modern buildings.