In our previous article, we introduced that raised floors have great performance in sound insulation and acoustics, but occasionally they can be the culprit of noise, such as crackling or squeaking. So what causes annoying squeaks from raised floors, and how do you avoid and fix them? In this blog, HUIYA experts will explain it to you.

What Causes Raised Access Floor Crackling?

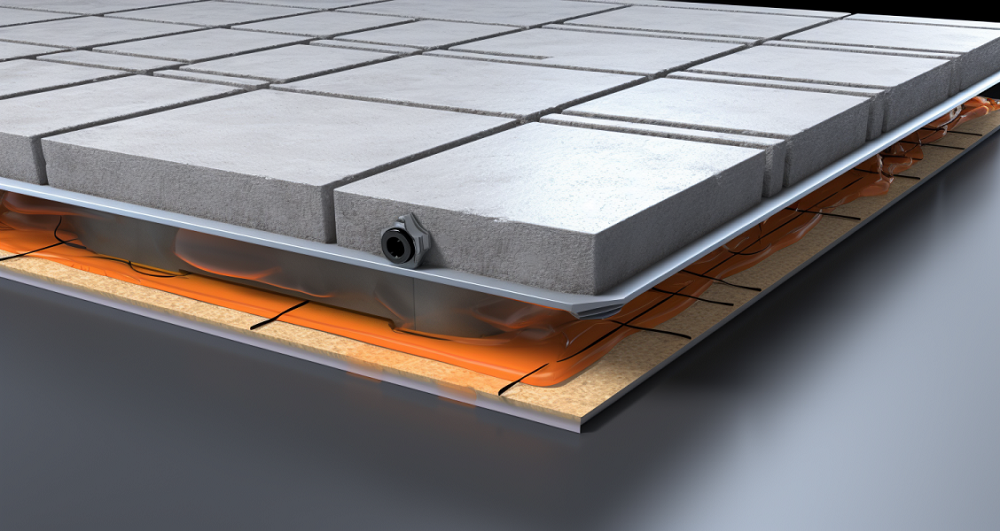

Raised access floors are designed to provide a stable and flat surface for foot traffic and to house services like electrical wiring, plumbing, and HVAC systems. However, they can sometimes produce a crackling or popping noise when walked on. Several factors can cause these noises, including:

- Subfloor Issues: If the subfloor below the raised access flooring is not perfectly level or has imperfections, it may cause the raised floor tiles to move slightly when pressure is applied, leading to crackling noises.

- Improper Installation: If the raised floor system is not installed according to the manufacturer’s specifications, including improper alignment, leveling, or securing of the panels, it can result in movement and noise.

- Damaged or Worn Components: Over time, the pedestals, stringers, or panels themselves may become worn or damaged. This can lead to instability and noise when the floor is in use.

- Loose Panels: If the floor panels are not properly secured or if they have become loose, they may move under foot traffic, causing a crackling sound.

- Environmental Factors: Changes in temperature and humidity can cause materials to expand and contract, which may lead to noise as the components of the raised floor system adjust.

- Debris and Obstructions: Sometimes, debris like small particles or objects can get lodged beneath the floor panels or between the joints, causing a crackling sound when the panels are stepped on.

- Structural Movement: The building itself can settle or shift slightly, which may affect the raised floor system and cause noises.

- Heavy Loads: Placing loads on the raised floor that exceed its designed weight capacity can cause panels to deflect and potentially produce noise.

How To Fix Squeaky Raised Access Floor?

To address crackling in raised access floors, it’s important to identify the exact cause. This may involve inspecting the subfloor, checking the condition of the panels and support structures, ensuring that the environment is controlled to prevent excessive expansion or contraction, and making sure that the floor system is clean and free of debris. In some cases, maintenance or professional repair may be necessary to fix loose or damaged components and to ensure that the floor is properly installed and leveled.

Here are some common methods to fix a squeaky raised access floor:

1. Tighten Loose Components

- Examine the Panels: Check for any loose panels by gently tapping on them or walking over them to identify where the noise is coming from.

- Secure Panels: Once you locate a loose panel, ensure it is properly seated on the pedestals. If necessary, adjust the pedestal heights or tighten the fastenings.

- Tighten Stringers: If the floor uses stringers (horizontal supports connecting the pedestals), make sure they are properly connected and secured.

2. Lubricate

Lubricate Joints: Apply a dry lubricant, such as graphite powder, to the joints and connections where the panels meet. Avoid using wet lubricants that can attract dust.

3. Level the Subfloor

Adjust Pedestal Heights: Use a level to check if the pedestals are correctly adjusted so that the panels are flat and even. Pedestals that are too high or too low can cause panels to rock and squeak.

4. Check for Debris

Clean Under Panels: Remove panels and vacuum or sweep out any debris that may have accumulated underneath, as it can cause panels to sit unevenly and create noise.

5. Replace Damaged Components

Inspect for Damage: Look for signs of damage or wear on the panels, pedestals, and stringers. Replace any damaged components as they can contribute to instability and noise.

Panel Dampening: If a panel is damaged or warped, consider using dampening materials or pads under the panel to reduce movement and noise.

6. Use Gaskets or Seals

Install Gaskets: Some systems allow for the installation of gaskets or acoustic seals between panels to prevent movement and reduce squeaks.

7. Stabilize the Environment

Control Climate: Maintain a consistent temperature and humidity level to prevent the expansion and contraction of flooring materials that can lead to squeaks.

8. Professional Assistance

Consult a Specialist: If the problem persists or you are unable to identify the cause of the squeak, it may be best to consult with a raised floor specialist for a professional assessment and repair.

When attempting to fix a squeaky raised access floor, always ensure safety by properly supporting any panels that are removed and following the manufacturer’s guidelines. If the floor is under warranty, contact the supplier or installer before attempting any repairs, as DIY fixes could void the warranty.

How To Avoid Raised Floor Crackling?

To avoid crackling in raised access floors, it is important to take preventive measures during the installation and throughout the life of the floor. Here are some steps that can help minimize or prevent crackling noises:

During Installation:

- Ensure a Level Subfloor: Before installing the raised floor, make sure the subfloor is level. Any unevenness can cause stress on the raised floor tiles, leading to movement and noise.

- Follow the Manufacturer’s Instructions: Install the raised floor system according to the manufacturer’s guidelines. This includes proper placement of pedestals, stringers, and panels.

- Use High-Quality Materials: Select high-quality materials for both the structural components and the panels themselves to reduce the risk of defects and subsequent noise.

- Properly Secure Components: Make sure that all components, including panels, pedestals, and stringers, are securely fastened and properly aligned.

- Professional Installation: Use trained and experienced installers who know how to correctly install raised flooring systems to minimize the risk of errors that could lead to noise.

After Installation:

- Regular Maintenance: Perform regular maintenance checks to ensure that panels remain tight and that there is no movement that could cause noise.

- Control Environment: Keep the environment stable in terms of temperature and humidity to reduce the expansion and contraction of floor materials.

- Avoid Overloading: Do not exceed the weight limits of the raised floor system to prevent undue stress and potential damage.

- Promptly Repair Damages: If any damage to the floor panels or understructure is noticed, repair or replace the affected parts immediately to prevent further issues.

- Keep Clean: Ensure that the area beneath the raised floor is kept clean and free of debris that could cause panels to sit unevenly or create noise.

- Inspect Regularly: Conduct regular inspections to catch and remedy any issues, such as loose panels or damaged pedestals, before they lead to crackling noises.

- Use Appropriate Coverings: Use floor coverings that are designed for use with raised floors to reduce the chance of noise and to prevent damage to the tiles.

- Access Floor Gaskets: Consider using gaskets or seals around the perimeter of the floor panels to provide a tighter fit and dampen any potential movement that could cause noise.

By following these guidelines, you can significantly reduce the likelihood of experiencing crackling noises from a raised access floor. If issues persist, consulting with the manufacturer or a professional raised floor specialist may provide additional solutions tailored to the specific installation.