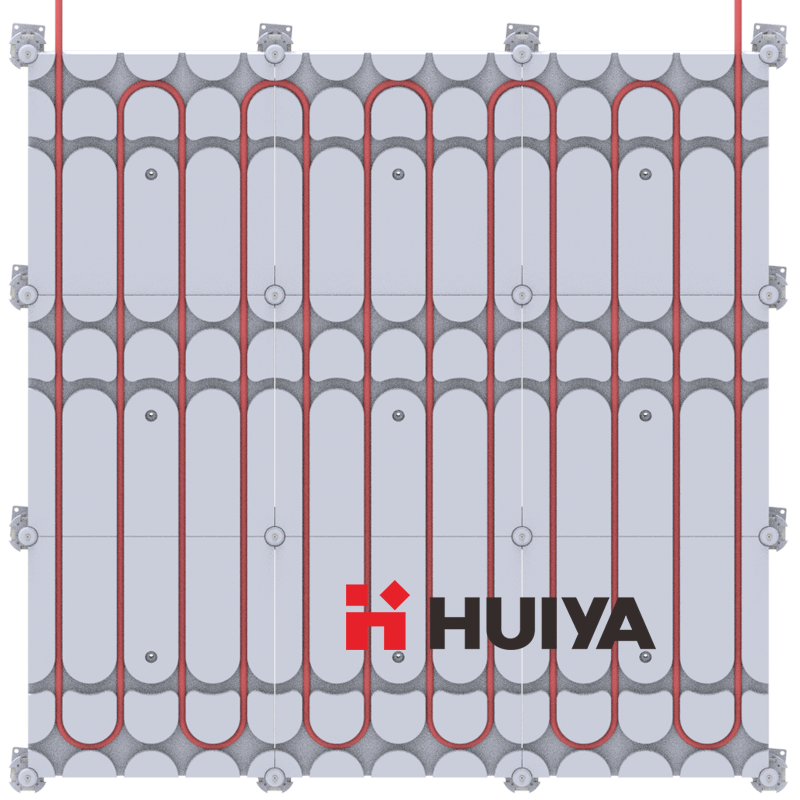

HUIYAINC Factory is A Business to Business(B2B) Type Raised FLoor Manufacturer In China. We Make Raised Floor Series includes:1:HUIYA GRC OMEGA Raised Floor(500x500x26mm) 2:HUIYA Steel Bare Raised Floor(600x600x33mm)With Corner lock Systems or Bolted Stringer Systems. 3:Calcium Sulphate Raised Floor(600x600x30mm) 4:Die Cast Aluminum Raised Floor Systems(600x600x55mm). 5:Anti-Static Raised Floor Systems (600x600x35mm). HUIYAINC Factory Provides various of Planings of Raised Floor Solutions About Raised FLoor and Understructure Customization.

Founded in 2005 in China, HUIYAINC is a company specialized in the field of The Raised Floor, False Floor, and Industrial flooring that represents the alliance of the best quality raised floor brands and a variety of systems. we are able to offer you technically sophisticated and high-quality double-floor systems. In addition, custom-made products and solutions are not a hurdle, but a challenge for our experienced team. HUIYA Technical Floor products offer important advantages for an ecological, modern, and responsible construction.

PERFORMANCE TO STANDARD GUILD PER CISCA

Recommended Test Procedures for Access Floors(2007)

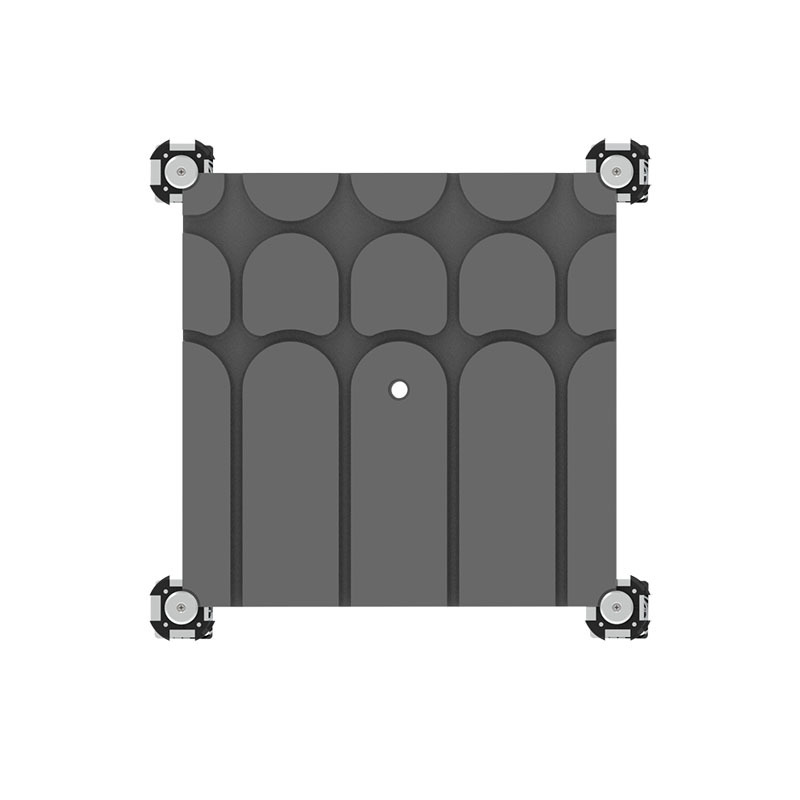

HUIYA Raised floor pedestal is made of Cold dipped Galvanised Steel Plate (Head Plate & Bottom ) and Solid M16 Rod. The Pedestal will be provides with an adjusting and locking nut to maintain the assembly at a selected height,which requires a deliberate action to change the height setting and which prevents vibration displacement.

HUIYA Raised Floor Stringer Size: 21x32x570mm and it is cold dip galvanized Steel to anticorrosion. HUIYA Raised FLoor Stringer is connection with Raised FLoor Pedestal.(We aslo called Stringer Bolted Raised Floor Structure).

How to distinguish PVC all-steel anti-static floor and HPL anti-static floor?

The manufacturer teaches you how to distinguish (PVC) all-steel anti-static floor and melamine (HPL) anti-static floor. To distinguish the difference between the two, we must first understand the two, let me introduce the two first:

1. Melamine (HPL) anti-static floor

HPL anti-static floor, also known as fireproof board, is made of melamine resin through component separation process. It is mainly made of melamine resin, plasticizers, stabilizers, supplements, conductive materials and adhesive materials. The HPL particles form a conductive network, making it anti-static. HPL anti-static floor has the characteristics of strong decorative effect, high wear resistance, dustproof and anti-pollution.

2. (PVC) all-steel anti-static floor

PVC all-steel anti-static floor is made of PVC resin through special processing technology, mainly made of PVC resin, plasticizers, stabilizers, supplements, conductive materials and mixed color materials. A conductive network is formed between the interfaces of the PVC particles, making it antistatic. PVC anti-static floor has the characteristics of strong decoration, elasticity, good abrasion resistance and no cracking.

How to distinguish between two kinds of anti-static flooring? Because the two kinds of anti-static flooring are made of different materials, they exhibit different physical properties. PVC anti-static flooring is elastic and has a soft feeling when pressed hard, making it more comfortable to step on. The HPL anti-static floor is slightly harder because of the characteristics of melamine resin, and it makes a loud sound when scratched by hand. Similarly, looking at the cross section, you can see the difference between PVC anti-static floor and HPL anti-static floor. It can also be concluded from the price that the anti-static floor of the two materials is different. The price of anti-static floor of the same brand and specification, melamine anti-static floor is more expensive than that of PVC anti-static floor.

How to choose PVC anti-static floor and HPL anti-static floor. First of all, these two kinds of anti-static floors are suitable for use in places with anti-static requirements such as computer rooms, operating rooms, and numerical control centers. Generally speaking, the northern cities choose PVC anti-static floor, and the southern cities choose HPL anti-static floor. What is the reason for this? In fact, the reason lies in the difference in temperature. Because the temperature difference between day and night in northern cities is large, when the temperature difference exceeds about 15 degrees, the deformation of the steel plate due to thermal expansion and contraction is different from that of the veneer material, which may cause the surface layer to crack, and the PVC surface layer is elastic. In the case of no cracking. However, HPL may crack due to its relatively hard material, resulting in a greatly reduced service life. But how to decide for a specific computer room? If the floor is laid with a constant temperature or a small temperature difference, where people often move around, or a place where equipment moves (such as an operating room), it is recommended to use HPL anti-static floor, because HPL anti-static floor It has strong abrasion resistance, dustproof and fireproof characteristics, and the floor will not be scratched or worn for a long time. If there is a large temperature difference and only a few people are required to walk around at ordinary times, and the equipment is sturdy and immobile (such as communication room), it is recommended to use PVC anti-static floor, which is characterized by long-term use without cracking, dirt resistance, dust and fire prevention.