Data centers house critical IT infrastructure and equipment that keep businesses running smoothly. The data center floor is an important component that can impact efficiency and operations. Using a raised floor with aluminum tiles offers unique benefits especially suited for data center environments.

What are the Raised Aluminum Tiles in the Access Floor System?

Raised aluminum tiles are modular panels used in access flooring systems to create a hollow raised floor above a structural base floor. Some key things to know about aluminum access floor tiles:

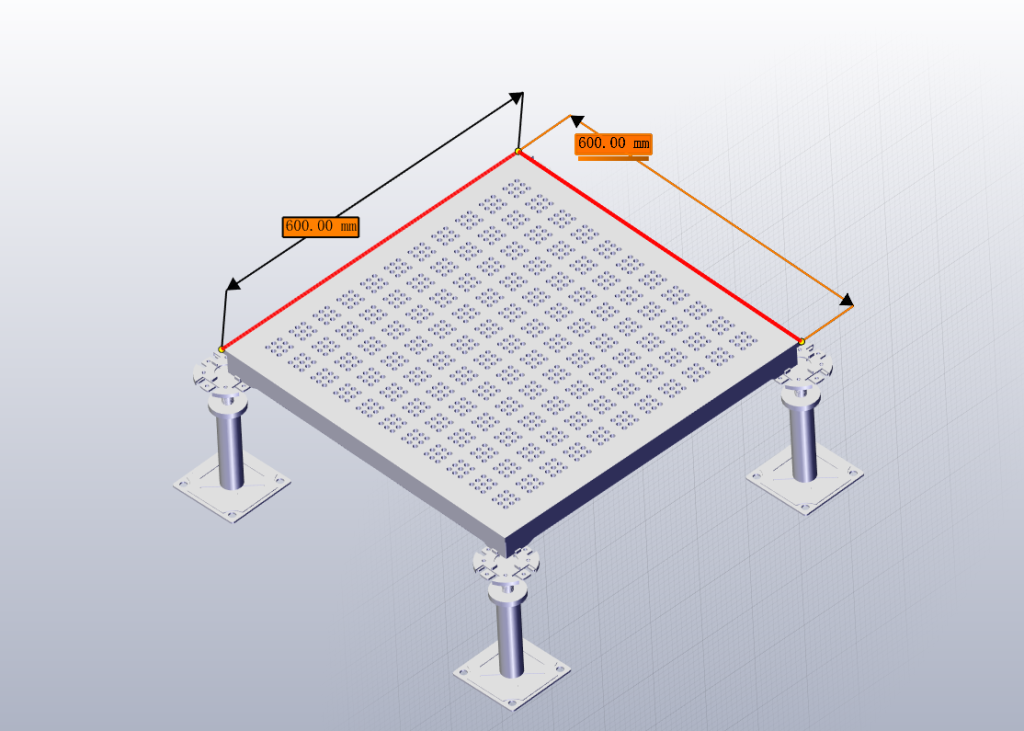

- Modular panels – The tiles interlock together and are removable to allow access underneath the floor. Standard sizes are 24″ x 24″ or 600mm x 600mm.

- Hollow core – The aluminum tiles have a hollow underside that creates an accessible cavity below the floor surface. The void is used for airflows, cables, wiring, etc.

- Lightweight – Aluminum tiles are lightweight compared to steel or concrete, often 2-3 lbs per square foot, making lifting and access easier.

- Load bearing – Quality aluminum tiles are durable and load-bearing to support equipment. Load ratings range from 250 lbs per tile up to 1000+ lbs.

- Perforated – Many aluminum tiles have perforated tops with small holes to allow air to flow through. Perforations range from 15% to 70% open area.

- Finished tops – Tiles can have various top finishes like bare aluminum, laminate, carpet, high-pressure plastic, wood veneer, etc.

- Pedestal support – The tiles rest on adjustable pedestals that provide the floor height and support the panels.

- Accessibility – Cables, wires, and airflow pass beneath the floor. Tiles can be removed as needed to reach the subfloor space.

- Configurable – The modular aluminum tiles allow data center layouts to be reconfigured by removing or swapping panels.

- Groundable – Aluminum tiles can be electrically grounded for static protection in electronic settings.

Why Should You Use Raised Aluminum Tiles in the Floor System?

Raised floors with aluminum tiles have clear advantages specifically for data centers. The many benefits in terms of cooling, access, safety, durability, and cost savings make aluminum raised floors an ideal choice over poured concrete or other materials. Below we explain the main benefits of using raised aluminum floor ties in Data Centers in detail:

- Improved Airflow and Cooling

One of the main advantages of using an aluminum raised floor in a data center is enhanced airflow and cooling capabilities. The void space underneath the raised floor serves as a plenum for delivering cooled air through perforated tiles to the equipment.

Aluminum tiles with high open areas allow cool air to flow through while preventing contamination from entering below. This helps maintain proper equipment temperatures and prevent hot spots. The perforations also allow air to flow out from the equipment back to the air handlers.

With a raised floor, you can strategically place floor vents and perforated tiles to optimize airflow. Cooling distribution is more efficient and targeted compared to cooling equipment from overhead diffusers.

- Flexible Layouts and Access

Data centers must adapt as equipment needs change. Raised floors with modular aluminum tiles make it easy to rearrange layouts. Individual tiles can be lifted and moved around to reconfigure rack positions and aisles.

Cables and wiring run underneath the floor between equipment. Accessing these below the tiles is made simple by just lifting the panels. This accessibility enables easy maintenance, inspection, troubleshooting, or installation of new cabling.

Cutouts can also be made in the aluminum tiles to install floor boxes with power, network, and A/V connections. Outlets and adapters are accessible by removing cutout tile sections while keeping cabling concealed.

- Enhanced Safety

A raised floor gives an added measure of protection from potential water leaks and flooding. Water damage is a major threat to electronic equipment. If a pipe burst overhead, the void space below the tiles would contain the water until it can be cleaned up.

Aluminum tiles are non-conductive and minimize static build-up. This is safer for sensitive electronics that could be damaged by electrostatic discharge events. Grounding pins can also be integrated with the raised floor system.

Panels are typically fire-resistant and have high load ratings. This ensures equipment loads are properly supported while also containing spreading flames in a fire emergency.

- Sturdy and Durable Construction

Data center floors must stand up to heavy equipment loads being rolled and shifted around. Aluminum tiles are very strong yet lightweight. Durability prevents damage that could come from chairs, carts, or heavy server racks rolling across the floor.

Aluminum tiles will not chip, warp or bend like wood or other materials. They maintain their shape and tile alignment. The panels interlock tightly and remain flat. Even after sections are removed and replaced, the floor level stays consistent.

Compared to steel or wood, aluminum better resists corrosion and rotting. Aluminum tiles maintain their new appearance with minimal maintenance requirements. This durability saves on replacement costs over the lifespan of the data center.

- Ideal for High-Tech Environments

The properties that make aluminum great for manufacturing electronics also make it well suited as a raised access flooring. Aluminum is non-magnetic and minimizes interference that could impact computing systems.

Being excellent conductors, aluminum tiles do not build up static charges. This helps prevent electrical discharge problems. Grounding and wiring can integrate directly with the conductive panels.

The material is inert and won’t offgas or release airborne particles. Aluminum tiles provide a clean and professional high-tech look fitting for a data center environment. The tiles are easy to keep clean as well.

- Cost Savings and ROI

Installing a raised floor with aluminum tiles does involve upfront investment. However, the cost savings in terms of cooling efficiency, change adaptability, and long-term durability make it well worth the ROI.

With more efficient airflow, cooling needs are reduced. This saves on HVAC energy and equipment costs. The quick access also translates to savings on maintenance labor.

Because of their longevity and strength, aluminum tiles may actually cost less than alternatives over the lifespan of the data center. Their lightweight nature requires less robust floor support too.

Considering the importance of data center infrastructure, the value added by raised floors makes them an easy choice for supporting critical systems and driving ROI.

What are the Challenges or Considerations When Installing Raised Aluminum Tiles in Data Centers?

Here are some common challenges or considerations when installing raised aluminum tiles in a data center:

- Weight capacity – Raised floors must be able to support heavy server racks, equipment, and concentrated loads. Proper structural support and tile strength ratings must be planned.

- Flatness and stability – Tiles must interlock securely and maintain alignment to keep the floor flat. Improper installation can lead to uneven or unstable floors. Ramps and trims are needed for smooth transitions.

- Tile sizing – Standard tile sizes can make planning easier, but cutouts may be needed for obstacles. Non-standard tile sizes may be necessary in some cases.

- Cable management – Cables must run cleanly under the floor between equipment. Sufficient height and access is needed for cable trays, conduits, and channels.

- Grounding – Multi-point grounding is crucial. Tiles and pedestals must connect properly, and grounding pins installed. Static control procedures should be followed.

- Perforated tiles – The open area percentage and hole pattern must match the cooling needs. Too little perforation restricts airflow. Too much reduces strength.

- Humidity – Moisture barriers and seals may be needed to prevent water vapor intrusion from below. Dehumidification helps control condensation risks.

- Cleanliness – During installation, strict cleanroom protocols ensure no dust or debris left under the floor. Vacuuming after cable work is important.

- Access and lifting – Server racks or heavy equipment make removing some tiles difficult. Special lifting equipment may be required in tight spaces.

- Coordination – Electrical, cooling, fire suppression, and flooring work must be planned together. Cutouts for floor boxes require alignment.

- Testing – Pressure and leakage testing ensures sufficient sealing and air control. Thermal imaging can identify cooling issues.

If planned out properly, the raised floor will support data center needs both now and well into the future. As infrastructure evolves, the flexibility and longevity provide long-term value derived from the initial investment. So take advantage of aluminum tile capabilities to create a state-of-the-art data center floor that allows your critical IT systems to operate reliably and efficiently.