On the office floor, aren’t power cords and cables all tangled up? It can be very dangerous as it may cause someone to trip and fall! We want to keep the floor clean so that no employees get injured. The OA floor introduced in this article is designed to keep the office safe and clean by storing the usually tangled wires and cables under the floor. Recently, some tenants come equipped with OA floors from the start, but in many cases, you may have to arrange for it yourself. Therefore, this article explains the merits gained by introducing an OA floor. It also provides necessary information for selecting an OA floor, such as the main wiring methods, and the types and materials of panels. Those considering introducing an OA floor in their company should refer to this article.

What is an OA Floor?

An OA floor refers to a double-structured office floor aka office raised floor that creates a space between the floor surface and the building framework to accommodate cables and outlets. “OA” stands for “Office Automation,” which is used in the context of using equipment to automate and improve the efficiency of office tasks.

So Office Access Floor is a system installed under the floors of buildings such as offices and commercial buildings to conceal wiring and communication cables. This flooring system allows for the arrangement of wiring beneath the floor surface, creating a flat floor surface. Not only does it conceal the wiring for electronic devices, computers, and communication equipment in the office, beautifying the space, but it also provides a convenient mechanism for the protection and management of wiring. Additionally, it offers flexibility for office reconfigurations or expansions, and makes the repair or replacement of wiring easy, thus facilitating the maintenance and alteration of facilities.

Advantages of OA Raised Floors

The primary advantage of converting office floors to OA floors is that it allows for a comfortable foot environment by storing wires such as telephone lines and LAN cables under the floor. This significantly reduces the risk of injuries from tripping over exposed cables and the risk of losing important data due to cable damage.

Offices with OA Floors vs. Offices without OA Floors

Offices without OA Floors:

- Cables are scattered and unsightly

- There is a risk of tripping over exposed wiring and getting injured

- There is a danger of losing data due to cable disconnection

- Cleaning is troublesome

Offices with OA Floors:

- All cables are stored under the floor, which looks neat and tidy!

- No exposed wiring, so passage is safe

- No worries about data loss due to disconnection

- Cleaning is easy

Types of OA Raised Floors

There are different types and designs of OA floors available, with adjustable floor material surfaces and heights. Therefore, they can be customized to fit office designs. There are also OA floors made from environmentally friendly materials available, contributing to the creation of a sustainable office environment.

Installation Types of OA Raised Floor

The installation methods for OA floors can be classified into two types:

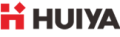

- Adjustable pedestal type OA floor is installed by placing panels on top of adjustable-height pedestals.

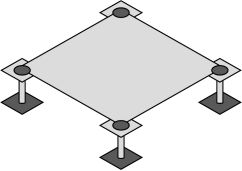

- Lay-in type OA floor is installed by directly placing panels on the floor without using pedestals and fitting them together without gaps.

Please refer to the table below for the features of each OA access floor installation methods:

| Adjustable Pedestal Type OA Floor | Lay-in Type OA Floor | |

| Picture |  |  |

| Advantages | Can be installed on uneven floors by adjusting the height of each pedestal – Fixed pedestals on the floor provide excellent seismic resistance | Construction is speedy.Since there is no need to drill screws into the floor, the building is not damaged. |

| Disadvantages | Time-consuming installationThe need to drill screws to fix the pedestals can damage the floor | There is no height adjustment feature, so it can only be installed on a level floor.Because the panels are not fixed to the floor, the seismic resistance is somewhat inferior compared to the post system. |

Material Types of OA Raised Floor

OA flooring characteristics vary depending on the material used. The main materials utilized are:

- Metal

- Plastic (Resin)

- Concrete

Please refer to the table below for the characteristics of each material:

| Metal | Plastic (Resin) | Concrete | |

| Advantages | High strength and easy to walkWide variety of load capacity typesMany manufacturers collect, reuse, and recycle products that are no longer needed.Lightweight and easy to carryOften made of aluminum or steelAluminum panels are suitable for computer rooms and mechanical rooms.Excellent recyclabilityGood walking feel | Material costs are lowLight weight and less burden on buildings No need for adhesive or screwsEasy to replace panelsRelatively cheap | Almost no hollow sound when walkingExcellent performance in blocking “noise” which is said to be the cause of communication failures and machine malfunctionsThe feeling of walking is similar to that of a normal floor |

| Disadvantages | Material and construction costs high | Poor load-bearing performanceCompared to concrete or metal, the walking feeling is unreliable.Footsteps are easy to hear (sound absorption measures are required) | HeavyMaterial costs are highDisposal costs tend to be highIf the panel falls off when replacing it, there is a high risk of damaging the wiring When disposed of, it will be treated as industrial waste. |

Plastic is inexpensive and convenient, but it has low load-bearing capacity. Therefore, it is not highly recommended for offices with high foot traffic or where the weight of furniture and equipment is a concern. In the case of concrete, disposal costs tend to be higher because it becomes industrial waste when discarded.

Wiring Method Types of OA Flooring

Next, let’s check the differences in wiring methods:

- Under-panel wiring (Support Type OA Floor Wiring Method) – There is a method of running cables under the panels (between the columns and legs), and

- Groove wiring (Stand Type OA Floor Wiring Method) – There is a method of laying the cables along the grooves in the panels and covering them with a protective cover.

Please refer to the table below for the characteristics of each wiring method:

| Under-panel wiring | Groove wiring | |

| Advantages | Large wiring capacityHigh flexibility in wiring (can be routed vertically, horizontally, or diagonally) | Easy to change wiring after installation |

| Disadvantages | Changing wiring after installation is labor-intensive | Limited wiring capacityCan only wire along the grooves (vertical and horizontal wiring only) |

Differences Between Each Type of OA Raised Floors

Up to this point, we have introduced the types and characteristics of OA floors. Before choosing the OA raised floor for your office, check out the main points once again by referring to the table below for the OA floor type comparison:

| Metal | Plastic | Concrete | |

| Installation Method | Pedestal Support Type | Loose Stand Laying Type | Loose Stand Laying Type |

| Wiring Method | Wiring under the panel (between columns and legs) | Wiring under the panel (between columns and legs) | Wiring along the panel grooves |

| Floor Height Adjustment | Possible | Not possible | Not possible |

| Wiring Capacity | Very large | Large | Small |

| Load Bearing | 3000–5000N | 2000–3000N | 3000–5000N |

| Ease of Wiring Changes | Difficult | Difficult | Easy |

| Walking Comfort | Easy to walk on | Hollow sounds, somewhat difficult to walk on | Very easy to walk on |

| Cost | High | Low | Somewhat high |

| Construction period | Minimum 2 week ~ | Minimum 1 week ~ | Minimum 1 week ~ |

Top 5 Points to Consider When Choosing OA Access Floors

The primary purpose of installing OA floors is to conceal cables and cords under the floor, but the choice between types depends on the intended use of the office and construction conditions.

1. Construction Period & Cost

The first point is the construction period and cost. There is a difference in both construction period and cost between the “loose laying type” and the “column type.” The loose laying type is chosen by many companies because it takes less time to construct and costs about half as much as the column type. If you have a limited construction period and budget, you might want to consider the loose laying type.

2. Wiring Method & Wiring Storage Capacity

The second point is the wiring method and the wiring storage capacity. The under-panel wiring method has advantages such as a larger wiring storage capacity and greater flexibility in wiring compared to the groove wiring method. Also, with the column type, it’s possible to increase the storage capacity by adjusting the height of the legs due to floor height adjustment. However, you will need to design the wiring to prevent interference. On the other hand, the groove wiring method may have a smaller wiring storage capacity, but it allows for neat organization of wires along the grooves, preventing interference. The ease of wiring and maintenance is also a benefit of the groove wiring method. It is easy to change or add wiring by simply removing the cover. Consider the “number of wires” such as power, network cables, and phone lines to decide which one is better. If you have fewer wires or plan to change layouts or expand in the future, the “groove wiring method” is recommended.

3. Appropriate OA Floor Height Based on Wiring Volume

Choose the height of the OA floor according to the amount of office wiring. If there is a lot of wiring, adjust the height of the OA floor to ensure sufficient space. Choosing the appropriate height makes wiring management easier and keeps the office looking neat.

- For an office with about 20 general staff: Low-profile loose laying type (height 40mm)

- For an office with about 50 general staff: Low-profile loose laying type (height 50mm)

- For an office with more than 50 general staff: Low-profile loose laying type (height over 50mm), Column type (with level adjustment)

- Server room: Column type (with level adjustment)

4. Load Bearing

The load-bearing capacity of the OA floor must match the weight of the equipment and furniture that will be installed. Overloading can damage the OA floor, so check the weight of the equipment and furniture and choose in accordance with the specifications of the OA floor. If the load-bearing capacity is insufficient, the stability of the floor may be compromised.

- 3000N – Suitable for offices with standard fixtures installed, such as office furniture, libraries, and multifunctional equipment.

- 4000N – Designed for heavy items such as large archives/bookshelves and small server equipment.

- 5000N – Suitable for large electronic equipment such as computer rooms and server rooms. Ideal for large offices, companies, schools, banks, and government agencies.

5. Material

OA floors are available in materials such as resin, concrete, and steel, each with different characteristics. The material affects the durability and design of the OA floor. Choose according to the atmosphere and purpose of the office, considering the balance between appearance and function.

Considering these points, choose the OA floor that suits your company. It will significantly impact the efficiency and comfort of the office.